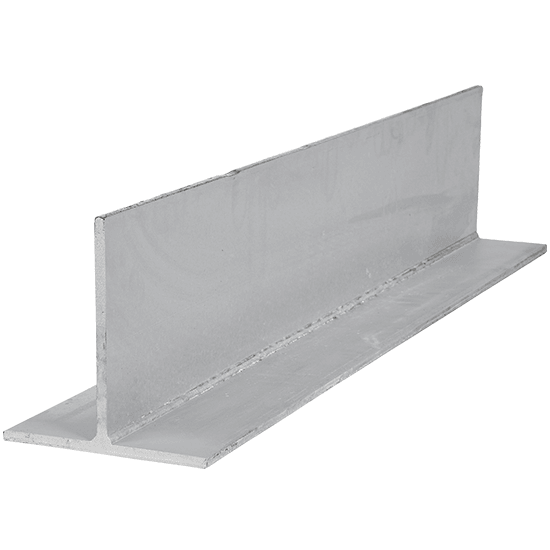

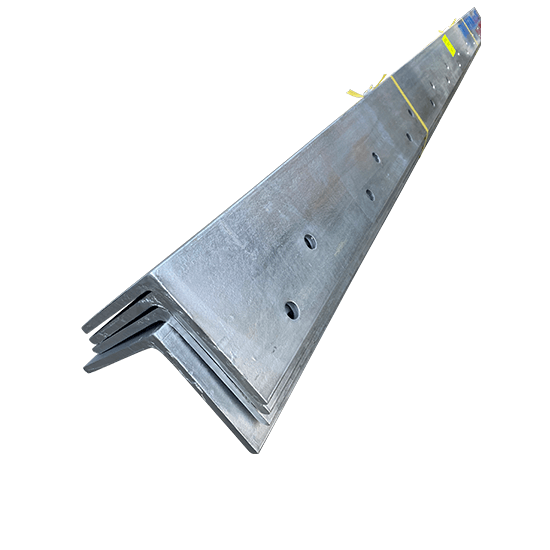

Concrete Lintels are pre-stressed and made from high strength concrete (65MPa) which gives the lintels their superior structural capacity.

Because concrete lintels are made from such high quality concrete they are more durable than steel lintels.

This makes them ideal for use in extreme corrosive environments such as coastal locations.

The load carrying capacity of an Ultralintel increases significantly when the composite beam action from the brickwork over is taken into account.

This composite strength rises as the number of brick courses above increases.

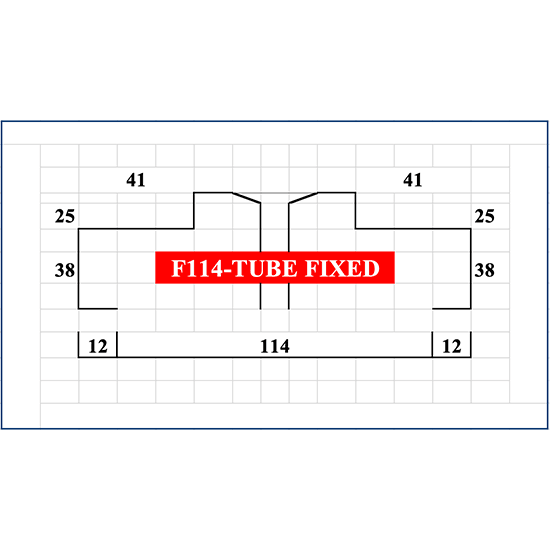

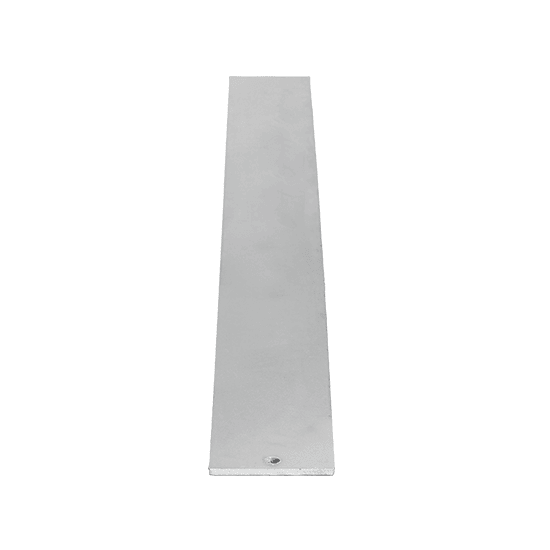

We have two lintel sizes available 110mm x 80mm and 110mm x 170mm, which suit standard brick courses and can be easily rendered, lined with plasterboard or external sheeting.

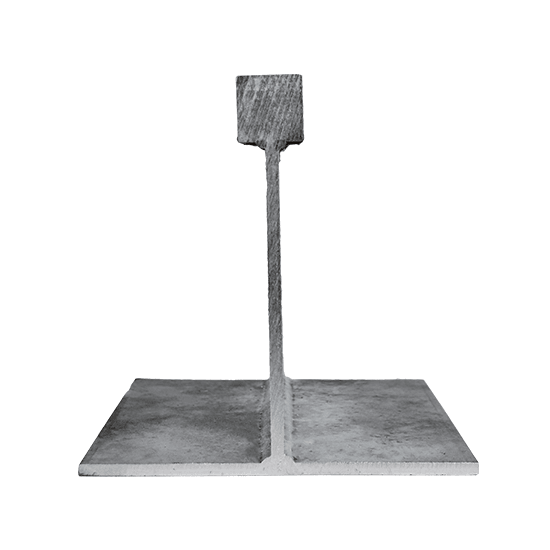

INSTALLATION

Concrete Lintels are typically installed by a Builder or Bricklayer and it is very important that the following instructions are followed during installation:

- Lintels must be placed with the rough side facing up in order to provide a proper key into the mortar above.

- Lintels must be propped at intervals not exceeding 1500mm until the mortar has matured.

The minimum bearing onto the brickwork is 100mm (spans up to 1200mm) and 150mm (spans > 1200mm).

- This is based on the assumption of a minimum brick crushing strength of 20 MPa.